Factors and methods affecting the performance of NdFeB

NdFeB permanent magnetic material has attracted much attention for its superior magnetic properties since it was developed, known as “magneto”, with the continuous growth of market demand, the production process and magnetic properties of NdFeB have been continuously developed and improved. Remanence, coercivity and maximum magnetic energy product are used to measure the properties of magnetic materials.

Remanence Br

If the magnet analogy sponge, remanence is like sponge water absorption saturation, this time shows the magnetic force value of the magnet. It refers to a magnet in a closed circuit environment magnetized by the external magnetic field to technology saturation after withdrawal of the external magnetic field, the magnetic induction intensity of the performance of the magnet.

Coercivity Hcb and intrinsic coercivity Hcj

The water in the sponge is absorbed to the maximum, and then the water pressure is pushed out, and there is no water in the sponge, the pressure used is like coercivity. It is the value of the reverse magnetic field intensity required to reduce the magnetic induction intensity to zero when the magnet is magnetized in reverse, but the magnetization of the magnet is not zero, it’ just that the reverse magnetic field added cancels out with the magnetization of the magnet. If the external magnetic field is withdrawn, the magnet still has a certain magnetic property. The intrinsic coercivity is the reverse magnetic field intensity required to reduce the magnetization of a magnet to zero.

Maximum magnetic energy product (BH)max

The sponge is saturated with water and the total amount of water in it can be understood as the maximum magnetic energy product. It represents the magnetic energy density established by the space between the poles of a magnet, that is the magnetostatic energy per unit volume of air gap, is the maximum value of the product of Br and Hcj, its size directly indicates the performance of the magnet.

We will discuss what determines the performance of NdFeB? How to improve the performance of magnetic materials by technical means? And how to avoid the use pf magnetic properties without loss.

The raw material composition and production craft of strong NdFeb determine its innate magnetic performance, and after becoming a strong magnetic products, its working environment(including temperature, humidity and other factors) will affect the play of its innate magnetic performance,improper use, permanent demagnetization will occur.

1. Effect of raw material composition on the strong magnetic properties of NdFeB

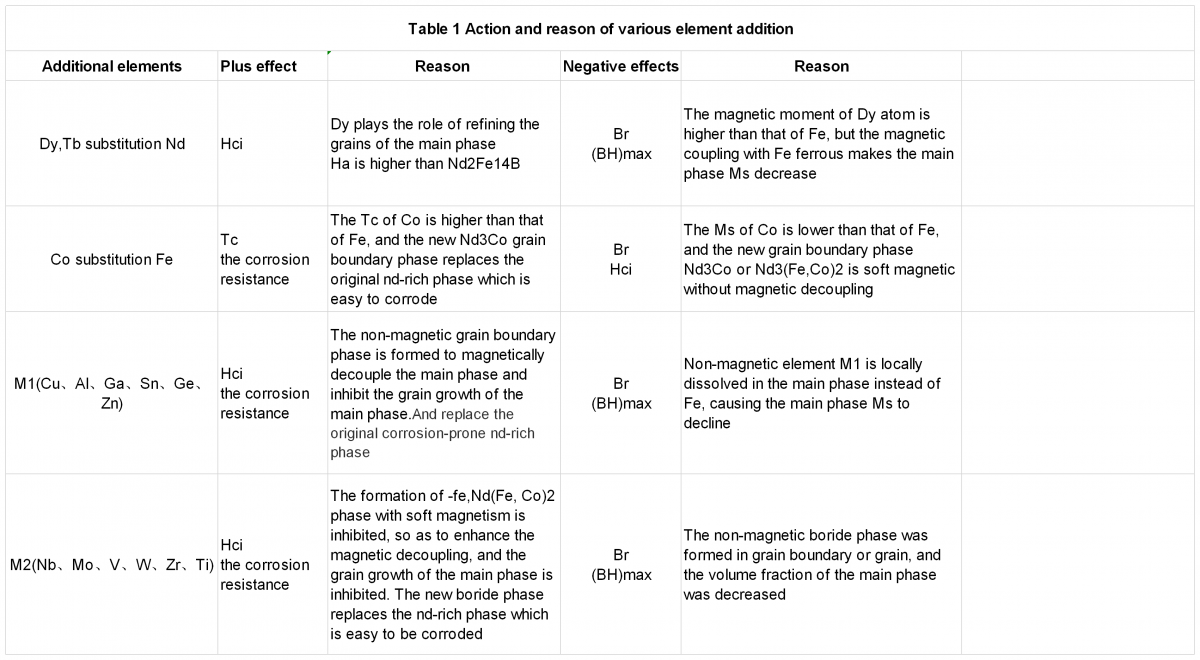

Strong NdFeB is a magnetic material made of rare earth metals neodymium, pure iron and boron by powder metallurgy. To further enhance the magnetic properties of NdFeB, additional elements can be added to the ternary Nd-Fe-B material, however, the effect of the addition of elements on the properties of magnets maybe bidirectional, the addition of elements should be determined according to the specific requirements of the use of strong NdFeB magnetic properties.

2. Effect of production technology on strong NdFeb properties

New technologies and processes are emerging to obtain high performance NdFeB permanent magnets. In the process of sintering NdFeB, the main problem is to prevent the precipitation of α-Fe phase and the oxidation of alloy, it is difficult to get the ideal microstructure. New processes and methods are constantly emerging to solve these problems in practice, for example: add antioxidants、lubricant, and adopting rapid quenching and slinging strip method to preparation magnet; ingot and homogenization and sheet casting process; two-phase preparation process, wet-pressing process etc.

The greatest benefit of adding antioxidants is the reduced oxygen content of the final magnet, at the same time the magnetic powder can be ground more fine, this is good for the improvement of coercivity, and also good for the improvement of coercivity due to the decrease of oxygen content. Compared with the traditional process, the intrinsic coercivity of the magnet with antioxidants can be improved by about 160KA/M.

Adding lubricant reduces friction between magnetic powders, the fluidity of magnetic powder is improved, the orientation is improved, and the remandance is improved.

The NdFeB strip thickness of 0.25~0.35mm prepared by sling with method can completely eliminate the α-Fe phase.The anti-oxidation ability of the powder was enhanced by slapping method, the grain size of magnet decreases, the coercivity has been greatly improved.

3. Effect of working environment on NdFeB strong magnetic properties.

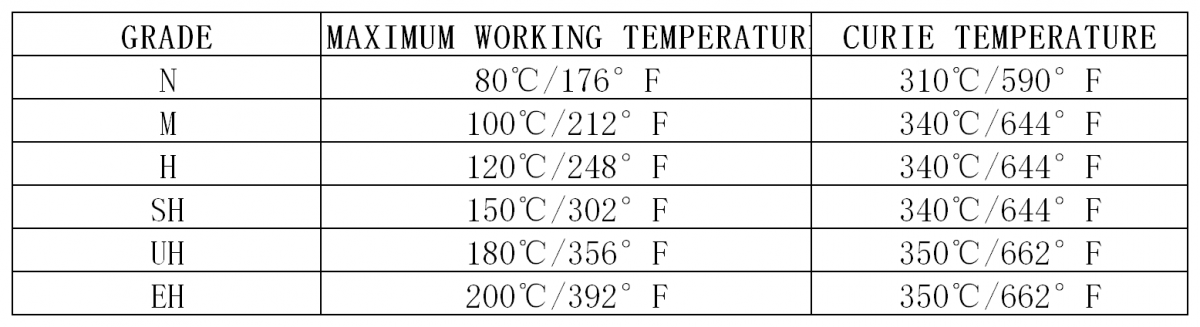

Temperature: NdFeB strong magnet has a strict working temperature limit, and the magnet may demagnetize when it is higher than the working temperature, and the demagnetization of the magnet will be irreversible when it is higher than the curie.

Humidity: Sintered NdFeB is a magnetic material pressed by powder metallurgy, its internal structure is void, very easy to oxidize, therefore sintered NdFeB will be used for corrosion protecting coating treatment. However, the coating can’t fundamentally deal with the influence of environmental humanity on the magnet. The drier the environment, the longer the magnetic properties of the magnet.